1/5

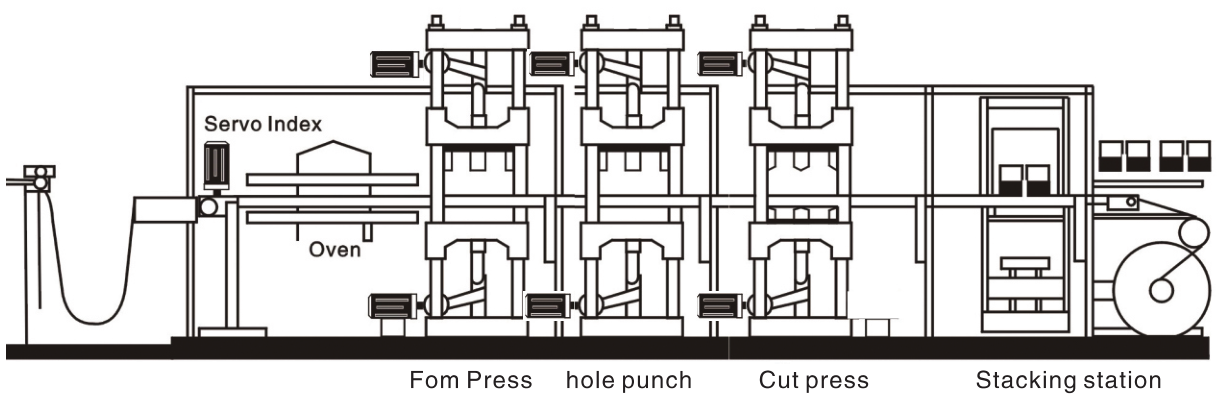

2in1&3in1&4in1 oven type thermoforming machine

Quick Details

OEM:

Available

Sample:

Available

Port:

NingBo

Payment:

L/C,T/T

Place of Origin:

China

Shipping:

Support Express · Sea freight

Supply Ability:

2 set per month

Quick Details

- Forming Area800*600mm / 700*500mm/530*400mm

- Depth of Draw under sheet120 mm Max (others at request)

- Depth of Draw above sheet120 mm Max. (others at request)

- Suitable materiaPP PET PS PVC BOPS

- Material Thickness Range0.2-1.5mm

- Dry run Speed60cycles/min Max.

- 4in1Form+Hole-Punch+Trim+Stack

- 3in1Form+Cut+Stack

- 2in1Form/Cut +stack

Shipping fee

Shipping fee

Design Feature

*4in1&3in1 for Form+Hole-punch+Trim+Stack

*2in1 for forming and cutting at the same station

*Full Servo Drive

*Air pressure forming + vacuuming forming

*Tool with floating knife

*Robot stacker with hop mode and A/B mode

*Precise Torque control for cutting force

|

|

Aplication

Clamshell,Tray,Container,lid,dish